Sedimentation Software Free Download Mac Based on Particle Size Fractions and Volume Fraction Updated FREE

Sedimentation Software Free Download Mac Based on Particle Size Fractions and Volume Fraction

i. Introduction

A large corporeality of research has been conducted on sediment disasters in urban drainage systems. In improver to an analysis of the characteristics of soil erosion in the watershed, a clarification of the internal phenomena has emerged as important. Causes of urban alluvion have been examined from various viewpoints, and the volume of sedimentation inside sewer conduits has been highlighted as a major problem. Soil accumulates in the drainage conduits and oftentimes blocks them, thus leading to flooding in urban areas. It is essential to forbid sediment deposition in sewers by means of proper design schemes, i.e., through enhanced design of sewer networks past considering sediment transport.

Researchers have studied the miracle of sediment ship by considering mainly open-channel states, such as in rivers [ane,2,3]. A river can be used for sediment deposition and transport analysis based on a variety of observed data. Information technology is possible to judge the range of influence by using hydraulic parameters. The relevant studies have primarily used data collection and analysis based on the river bed to calculate the rate of sedimentation. However, it is challenging to obtain data on sediment transport and sedimentation in urban drainage systems because sediment menstruum in sewer conduits is very unstable [4,five,6].

The results of the empirical process are hydraulic characteristics of a single fluid. It is impossible to model a phenomenon when a complex procedure occurs at the aforementioned time, and thus two-phase flow must be considered [seven,8,9,10,11,12]. Moreover, mixing occurs inside conduits when soil enters them [13,14,15,xvi].

Many studies were suggested for the sediment transportation. The Hydrass flushing gate and field validation of affluent propagation modelling were suggested for the flush cleaning of sewers [17,18]; a cleaning operation including installation of a sediment trap or a flushing sump/chamber in front of outlet [19]. The 1D De Saint Venant-Exner equations were practical to numerical modelling [20]. Even so, in that location is no application of ii-phase flow for the sediment transportation in urban sewer conduits.

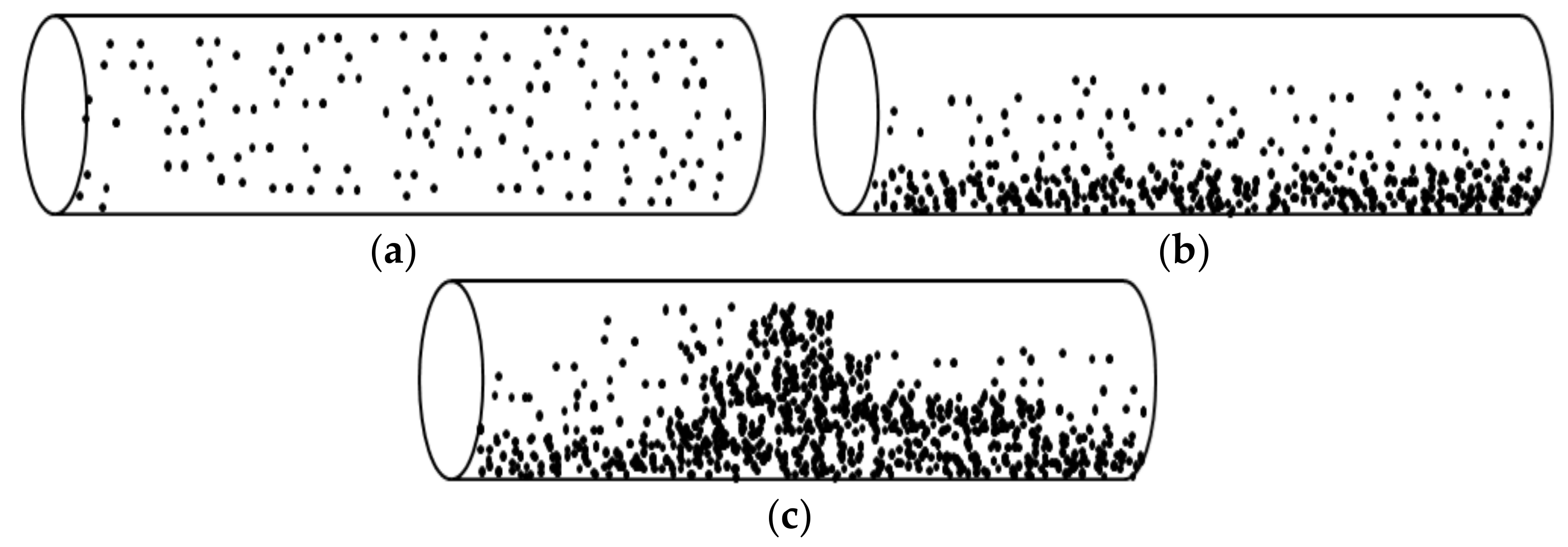

2-phase flow is an instance of multiphase flow and can occur in various forms. The results of empirical processes according to the hydrodynamic properties of single-stage fluids are unlike from those of phenomena involving a two-phase menstruum composed of soils and fluids. The ii-phase flow can exist classified as shown in Figure 1: homogeneous menses, where soil particles move uniformly throughout the pipe (Effigy 1a); separated menstruation or dune flow, where particles with high density settle at the bottom and flow (Figure 1b); and slug flow, where large bubbles are created and move (Figure 1c). The catamenia of mixtures of soil and water follows a ii-phase pattern, where homogeneous mixtures are as shown in Effigy 1a, and soil particles with high density settle at the bottom and motion as in Figure 1b. This study reports the modeling of two-phase flow patterns as shown in Effigy 1b.

In this study, an ANSYS-Fluent numerical model, a solver of computational fluid dynamics (CFD) models, was applied for analysis. It is amid the nearly widely used commercial CFD solvers in practical and academic research in mechanical and industrial engineering science [21,22,23].

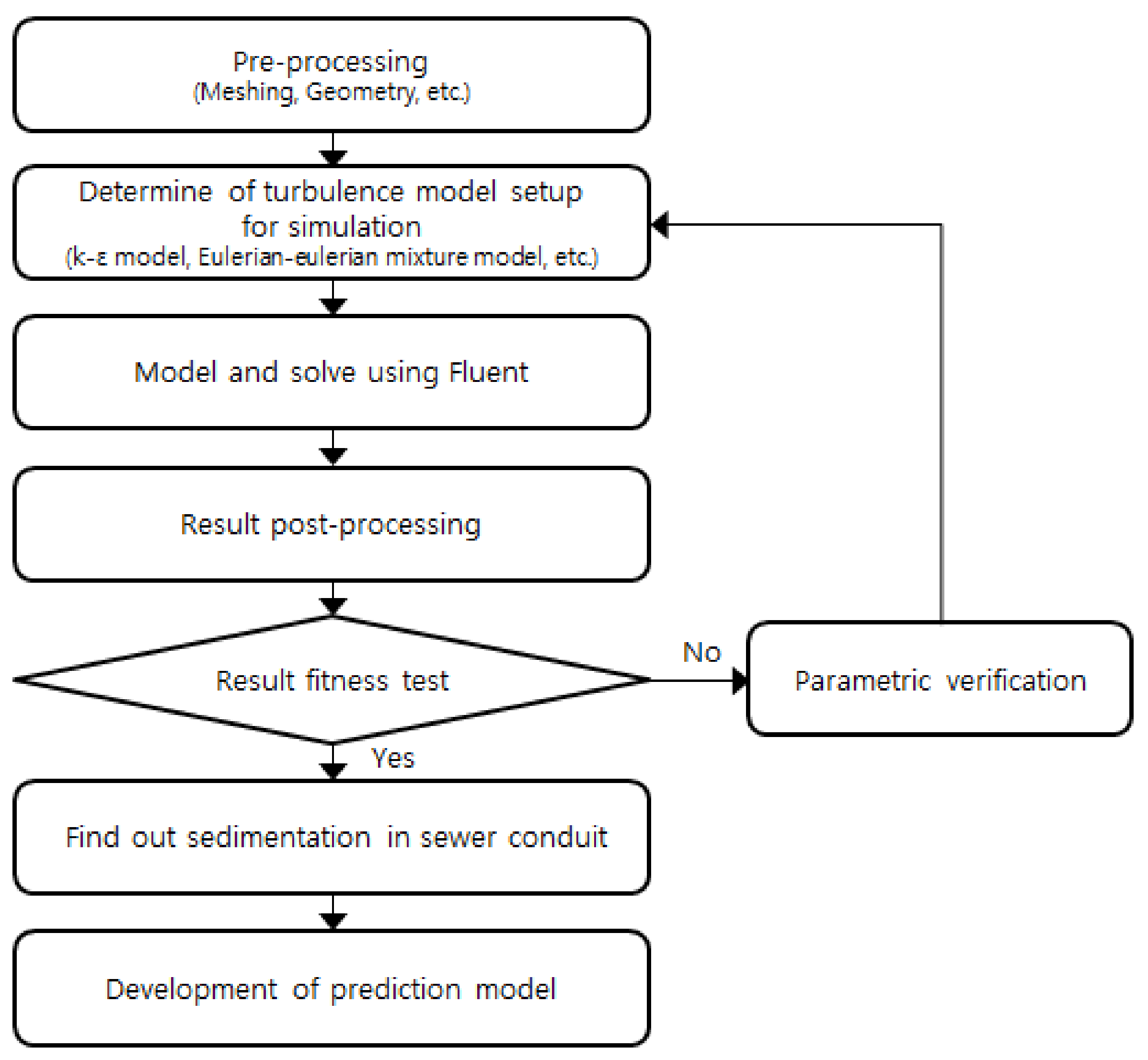

In the procedure of validation, diverse changes measured in an experiment involving a pipe performed by Nabil et al. [7] was simulated. The effects of inlet velocity, the size of soil particles, the volume fraction of soil, the catamenia characteristics of the water mixture, and soil distribution within the conduits were numerically investigated by using a two-phase mixture model. The characteristics of soil and h2o slurry were numerically investigated in pipeline flow. Conduits with horizontal locations were used in the simulation. Based on the results, the authors develop a sedimentation height formula to assess the discharge capacity of an urban drainage organization by considering sediments in conduits. A period chart of the analysis procedure is shown Effigy 2.

2. Methodologies

ii.1. Overview

Soil transfer inside conduits is complex to model considering of an insufficient amount of observational or empirical data. Moreover, the physical complexity of sediment transport, settling, sedimentation, and erosion in conduits must be considered. Parameters such as the critical flow rate, shear stress, particle backdrop, and hydraulic parameters in conduits must also be considered. Fluid flow within conduits cannot be characterized as involving a single fluid; it is modeled as two-stage period with soil. Therefore, it is necessary to consider interactions using both fluid statics and dynamics. The purpose of numerical modeling is the examination of mathematical models for two-phase fluid flow analysis.

In all problems involving CFD analysis, information technology is essential to decide the initial and boundary conditions. Information technology is important for the user to design a model to analyze and implement numerical models suitable for this. The solutions are obtained through proper operating procedures. In unsteady and turbulent flows, all variables used for analysis have different values in the overall flow areas from the initial values. Those (initial values) could be represented as the important variables [xx]. At that place are several assumptions for the modelling. The assumptions consist of:

-

The ii-phase flow of a single sewer conduit was imitation

-

The pipe channel instead of open channel was used for simulations

-

The mixture and turbulent flows was assumed

-

The same diameter of particle flows to a single sewer conduit.

ii.2. Governing Equations

To analyze the inflow rate of fluid containing soil particles, it is necessary to analyze the catamenia of two-phase fluids. Boris et al. used the eulerian-eulerian CFD model for the sedimentation of spherical particle concentrations [24,25]. Lixing analyzed the two-stage turbulence model in eulerian-eulerian simulations and Zhen et al. suggested a multi-dimensional eulerian two-phase model for sediment send [26,27]. Many studies used the eulerian-eulerian model for the particle transportation and this study uses an eulerian-eulerian model. The two-phases are handled and analyzed equally continua that are preserved, and the volume occupied past one cannot be occupied by the other. The concept of book fractions is hence introduced. These volume fractions are assumed equally continuous functions of infinite and time and their sum is always constant. The governing equations for all phases tin be obtained using the conservation equation for each. The modeling methods of two-phase flows, such equally a mixture of soil and fluids, using numerical analysis tin can be largely classified into an eulerian method that assumes that the soil particles are a continuum, like a fluid, and a Lagrange method that applies Newton's laws of strength and motion to the soil particles. The methods of analyzing soil particles every bit a continuum can exist farther classified into a unmarried-fluid model that applies continuity equations, momentum equations, and particle component conservation equations by handling a mixture of soil and h2o as a fluid, and a two-phase separation model that applies the laws of conservation to the soil particles and the fluid, respectively.

ANSYS-Fluent calls the to a higher place 2 models a mixture model [28], and an eulerian–eulerian model, respectively, and both have yielded very similar results in previous studies [7,9,10]. The same result of this study and previous studies is the sedimentation of a sewer conduit in the procedure of transport modelling. This written report uses the mixture model with a high computational efficiency. Although the mixture model handles the mixture as a single fluid, all component equations for the soil particles, gravitation, and interactions between fluids and soil particles, and within the soil particles tin be practical to the momentum equations. Its computation is relatively piece of cake, and thus is widely used to model a mixture of soil particles and fluids. In general, the assay of flow characteristics using a slurry composed of soil particles and fluids involves the use of an eulerian–eulerian two-phase menstruum model. The model is used to clarify the flow of soil particles as the motion of fluids.

The eulerian–eulerian method obtains a menses charge per unit field and a soil particle distribution field past solving the continuity Equations (one) and (2), the momentum Equations (iii) and (4), and the standard k–ε turbulence equation. In the thousand–ε turbulence model [29], the correlation term in the flow velocity variations is represented in a Reynolds' stress term past averaging the values of the Nävier–Stokes equation over fourth dimension under the assumption that a turbulent menstruation velocity varying in time can be divided into a time average menstruation velocity and a variant flow velocity. Each equation follows the laws of conservation of mass and momentum, suitable for analyzing the effect of turbulence on each boundary surface in an arbitrary inspection volume set to clarify the catamenia in a conduit of urban drainage systems. Equation (ane) is a continuity equation representing the transfer of momenta for pressure, viscosity, turbulent stress energy, the transfer of volumetric fractions, and densities per time of each phase based on the flow velocity components of momentum in Equation (ii).

In particular, the momentum equation should reflect interactions between soil particles and fluids; thus, Fc and Fd in Equations (iii) and (4) represent the elevate force and the lift forcefulness due to the interactions between the fluids and soil particles, respectively, for which commercial programs provide various models every bit options. This study applied the Syamlal–O'Brien model [30] as a particle viscosity and pressure model [31,32,33,34], and it was also used equally a drag force model. The continuity equations are shown every bit Equations (1) and (ii), and the momentum equations equally Equations (3) and (four):

where u is fluid velocity,

is the density of the fluid,

is the volume fraction of each phase,

is the vector differential operator, p is pressure, g is the gravitational abiding, and µ is dynamic viscosity.

2.3. Model for Analysis

To clarify the event of turbulence inside the conduits into which particles of fluid and soil are introduced, it is necessary to consider the turbulence model. When a fluid moves continuously, a laminar menstruation appears finally every bit shear strength attributable to the laminar viscous force between neighboring fluids equally a driving force. However, if menstruation velocity increases for the shear stress to go very strong, the transfer by the viscous force cannot bear this, such that the shear force is broken by very pocket-sized turbulent eddies that transfer the shear force to within the fluid. As flow velocity increases further, the size of the turbulent eddies decreases and the behavior of the fluids varies significantly depending on changes in time. The temporal average values of turbulent catamenia vary in a constant form and the fluctuation values have short temporal periods.

To clarify the flow composed of soil particles and fluids, it is necessary to analyze ii-phase fluids. This study used the eulerian–eulerian model and the g–ε model to clarify the continuity equations and turbulent movement. one thousand represents physically the turbulent kinematic energy, defined as turbulent perturbation velocity, which in plow is defined as turbulent dissipation rate. The k–ε model is an boil viscosity model, from which μt tin can be obtained through 1000 and ε in Equation (five):

Cu is a model constant that takes a value of 0.09 in full general [24]. In local areas, depending on the generation of sedimentation in conduits, turbulent stress can be modeled by computing 1000 and ε using two transport equations, such every bit Equations (6)–(eight):

In these equations,

represents the generated turbulent kinetic energy owing to the mean velocity gradients,

is the generated turbulent kinetic energy due to buoyancy,

represents the contribution of the fluctuating dilatation in compressible turbulence to the overall dissipation charge per unit,

and

are constants,

and

are the turbulent Prandtl numbers for 1000 and ε, respectively, and

and

are user-divers source terms [35].

Each coefficient in Equations (five)–(viii) uses the following values in the standard m–ε model such as Table 1:

,

,

, and

are unknown. The values of these constants are determined by numerous iterations involving data plumbing equipment for a wide range of turbulent flows. It finally becomes possible to accept them as below [36].

In the k–ε model, under the supposition that turbulent flow velocity varying in time can exist divided into temporal boilerplate menstruum velocity and fluctuation flow velocity, the Nävier–Stokes equation is a time-averaged equation to indicate the correlation term in flow velocity fluctuations under a Reynolds' stress term.

2.iv. Purlieus Weather

The purlieus conditions considered in this written report were various and related to the inlets, outlets, and walls in general. The inlets are areas in which all data related to the flows is known, for which the user tin ascertain flow velocity, pressure, characteristic length, turbulence strength, and temperature. The outlets can be used when all directions of flow in the outlets are known, for which data concerning the flows is unnecessary.

This study assumed that the arrival conditions did not alter over time or were due to other features. Because of this, simulations representing the phenomenon could be created by bold a diversity of outflows. The computation fourth dimension was too reduced to enable recursive computations. The boundaries for the sections used for analysis were the walls, and flow inlets and outlets, of which the former were constrained past a no-slip condition. The inlet of the conduit had the status whereby the fluids and soil particles compulsively flowed in, and the outlet had the same conditions as a natural outlet with outflow characteristics. Because the shapes of the inlets and outlets were not complex, the inlets were used as flow boundary conditions and the outlets as differential pressure level purlieus weather to set an outflow relationship. The following Tabular array 2 summarizes all of the analysis atmospheric condition.

2.5. Validation of Model

To verify the analysis, the results were compared with experimental results in [7]. The facilities used for the h2o–soil slurry flow experiment primarily consisted of a sump tank, a centrifugal pump, pipage, and a test part. The test part was a U-shaped pipe of length 10.55 m and inner diameter 150 mm. The book distribution in the slurry menses was measured using a radiation density meter and flow velocity distribution was measured through the impedance betwixt electrodes installed on the flooring of the pipe. The impedance between the electrodes represents the electric field formed past them as changed by the slurry. The slurry period rate was measured using an electronic catamenia rate meter. As an experimental method, 0.2–two.0 mm of soil particles and water were adjusted according to the given book fractions in a sump tank, circulated by a centrifugal pump through a test role and a visual office in turn, and were returned to the sump tank. Various measurements were performed during this time.

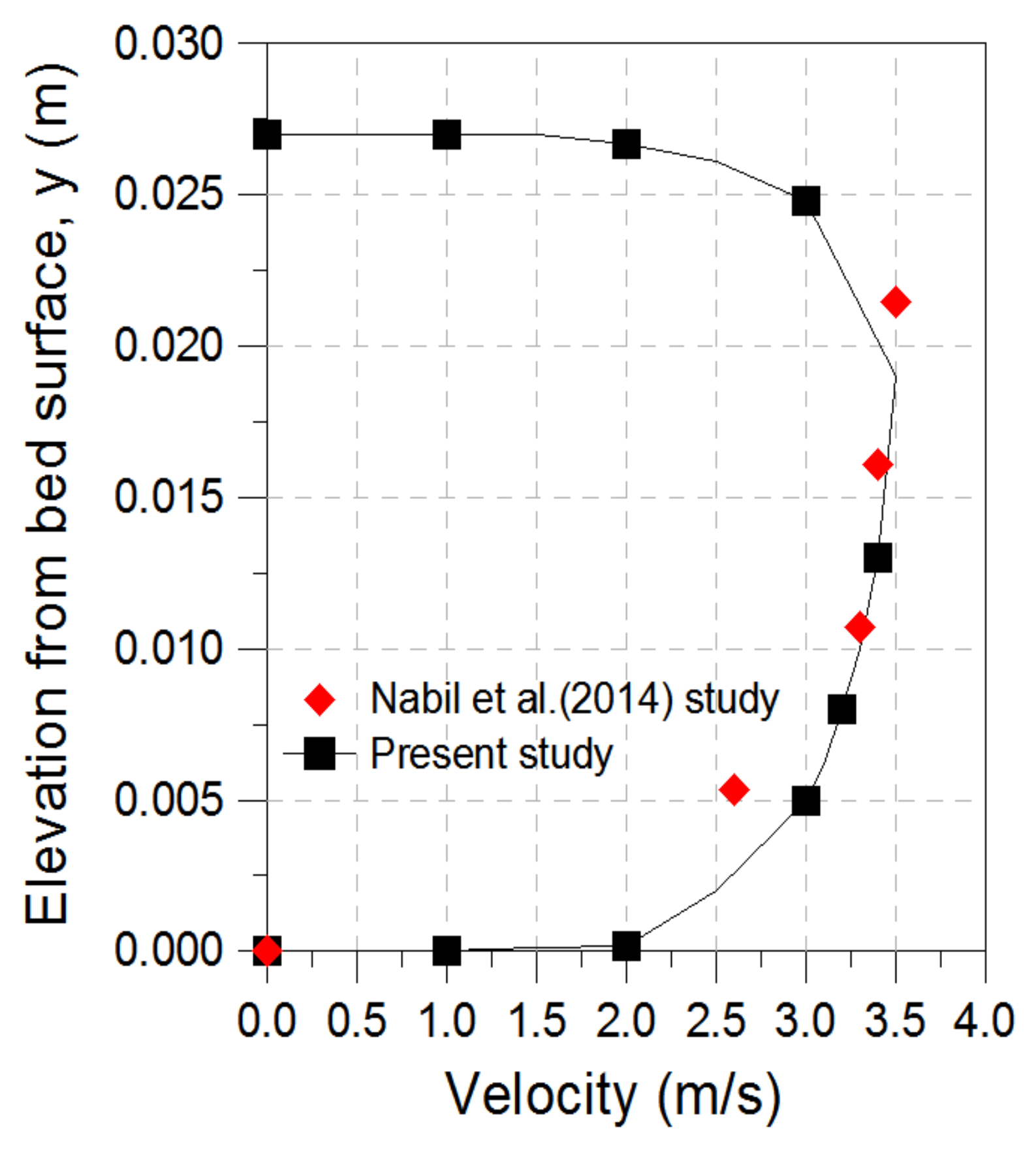

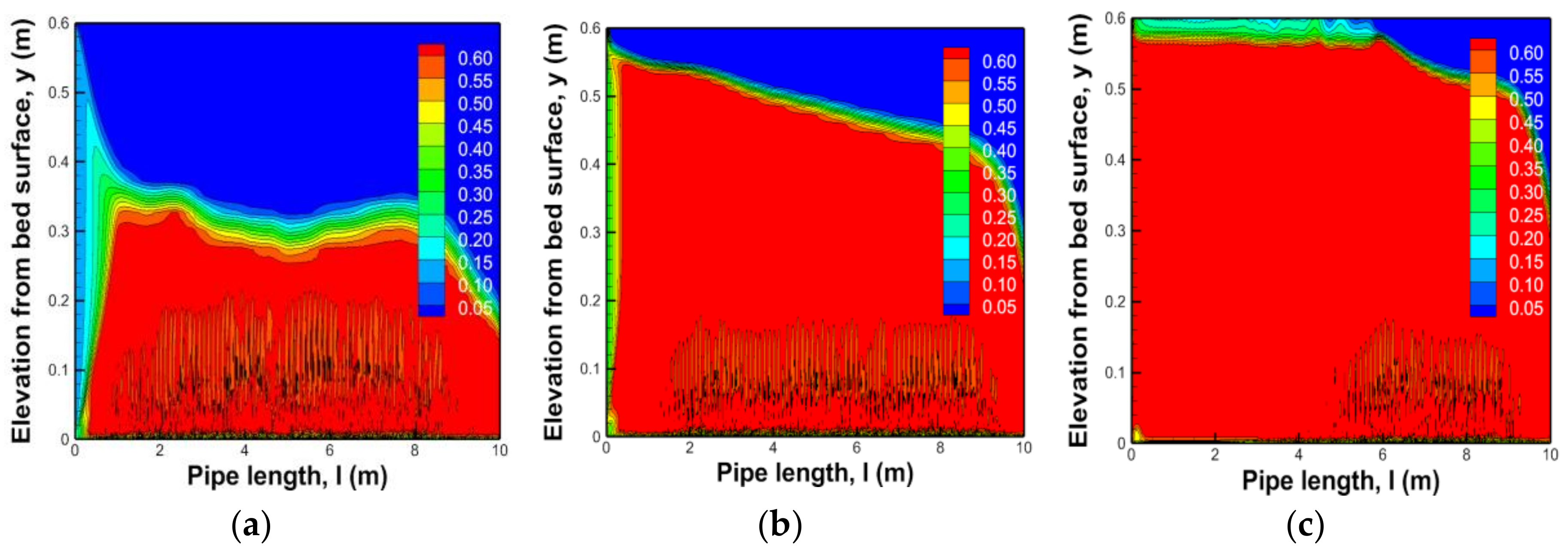

Table 3 shows conditions for the verification of the analysis. Figure three and Figure four show the book distribution of the soil particles and the menstruation velocity distribution of the mixtures in slurry, respectively. The one-time in the pipe, at relatively fast menses velocity, was slightly greater at the bottom of the conduit only was uniform on the whole at 30%, similarly to the distribution at the inlet, and the period velocity distribution of the mixtures was higher at the peak of the pipe than the lesser owing to the partial degradation of soil at the bottom. The results of the menstruation phenomena yielded predictions similar to the experiment results as shown in Figure iii and Figure four.

3. Slurry Flow in Sewer Conduits

The authors analyzed 63 simulation conditions based on the atmospheric condition listed in Tabular array 4. The computation was carried out up to a total of 500 s by applying a ciphering time interval ∆t = i south, where the ciphering was ready to repeat 10 times the internal computations (step length factor). Using very small values in repetitions of the computation could have led to a termination of the analysis during particle transport and deposition, but interval used in this study was large plenty to avert this upshot. It was thus confirmed that the results did non alter afterwards a certain time in the assay.

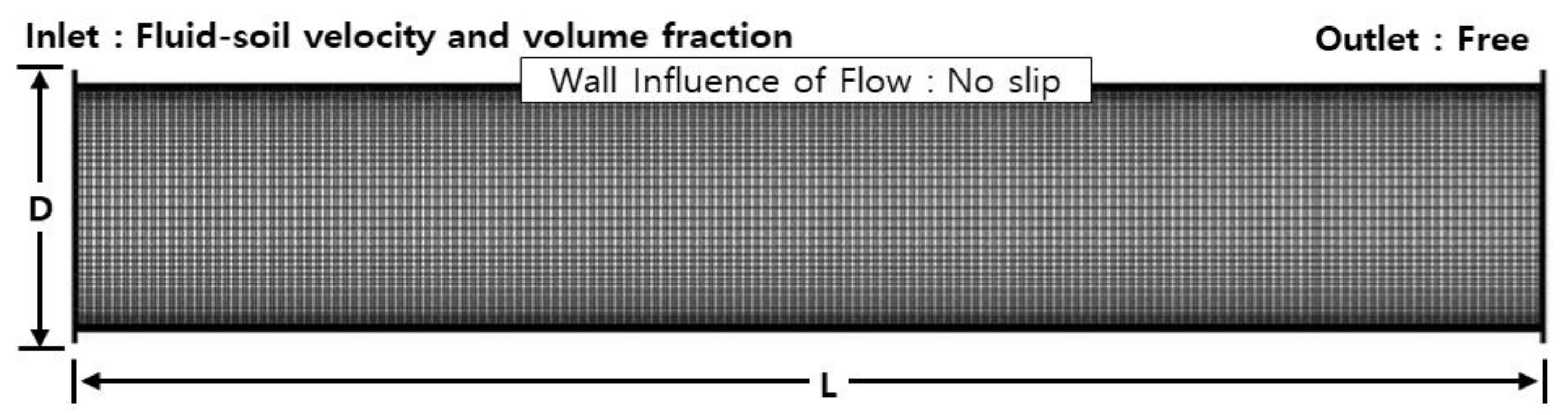

To simulate the deposition of soil flowing through a conduit, brusque conduits were used. For numerical simulations, a CFD assay was carried out for incoming mixtures by considering the shape of drainage conduits and the blazon of connexion of specific facilities. A total of 140,000 rectangular meshes, each 0.6 m in diameter and ten m long, were used; no symmetrical boundaries were applied but the shape of the unabridged conduit was represented. Triangular meshes were used to analyze the drainage conduits, whereas rectangular meshes are suitable for analyzing structures with circuitous shapes and are easy to create.

Figure five shows the area of numerical analysis and the mesh used for the drainage conduits. The meshes were generated using an internal mesh creation model of the ANSYS-WORKBENCH [37]. The soil passing through the drainage conduit had particles of unlike sizes, and their distribution needed to exist considered for modeling. Withal, this written report assumed uniform incoming particle size, and relied to the diameter of each particle to separately consider only the effect of the size of the inflowing particles on flow velocity and particle distribution of the mixtures.

The soil slurry flowing into the organization every bit conduit independent particles of dissimilar sizes. It was modeled by because the dispersion of particle size. However, only particle size influenced velocity and particle distribution of the mixture. We assumed that compatible particles were introduced by considering a single particle size.

3.ane. Changes to Flow Velocity and Fraction of Slurry Volume in Conduit

The flow velocity distribution of soil slurry in a conduit continually changes with fourth dimension, and is significantly affected by the distribution of sedimentation. If more than soil at a particular region accumulates than in other regions, its period rate increases, which causes information technology to be transported again to maximize the summit of the soil at some other location of the conduit. Through this process, the maximum sedimentation elevation of the soil slurry moves toward the exit along the direction of the outlet of a conduit, and a large amount of soil exits the conduit at a time. Therefore, when examining the volume fractions of soil in a conduit, regions of highest and lowest concentrations are found. These portions are discharged at different times. The menstruum velocity distribution along the radial direction of the conduit appeared to exist largely distorted from a parabolic form, which differed significantly depending on the positions of the high and low volume fractions of soil in this direction. The velocity distribution forth the longitudinal direction also varied profoundly. Every bit the book distribution of soil was high, the menses velocity of the mixtures decreased attributable to an increase in the interaction betwixt mixture particles and their viscosity; every bit the book distribution was low, the flow velocity of the mixtures increased.

An analysis was carried out to predict the effect and range of soil inbound into a conduit on discharge capacity through a transportation and precipitation process. Effigy 6, Figure vii, Figure 8 and Effigy 9 show the results of numerically simulating depositions in the conduit by assuming transportation and precipitation using a numerical model. In the figure, l is the length of the conduit. Effigy six and Figure vii show that the deposit forms in a conduit depending on changes in the book fractions at the aforementioned flow velocity weather, and list the results of the assay of i.0 mm and twenty.0 mm as examples.

In Table five, the ascertainment confirmed that the creation of sections of deposition increased along the direction of the outlet every bit particle size was relatively small-scale. This ways that the range of deposition was created in the same sections due to the upshot of turbulent diffusion, which transferred the soil relatively smoothly to the outlet. On the contrary, equally the particle size increased, degradation heights were created between the inlet and outlet because the range of turbulent improvidence was minor. It was confirmed that the overall discharge capacity decreased according to the increase in book fractions to block the conduit as the diameter of the soil was large. An increase in the book fractions can cause a turbulence phenomenon where the menstruation velocity distribution in the conduit is not uniformly continued to internal degradation.

As particle size increased, the drag strength and gravity acting on the particle increased to show larger deposit heights. The largest deposit was located at the stop of the conduit as particle size was pocket-size. Nevertheless, as mentioned above, the largest deposit occurring at a particular time moved toward the tail of the conduit over time for all particle sizes.

Figure 8 and Figure ix show the deposition miracle in a conduit according to changes in inflow velocity at the aforementioned volume fraction and list the results of assay for soil of diameters i.0 mm and 20.0 mm as examples. The results prove that the eolith height decreased as flow velocity increased. Thus, the strength of fluids according to an increase in flow velocity by section was greater than the resistance force of the hardened deposition boundary needed to motion the soil, which means an increase in friction owing to an increase in traction.

In Table 6, the results of the numerical analysis ostend that the eolith top increased with particle size and volume fraction of soil and decreased with an increase in flow velocity for the respective conditions. An increase in deposit acme increased menstruum velocity at the summit of the conduit and, as the size of the soil particles increased, the form of deposition was confirmed. In this event, degradation in a conduit tin can be said to be a process where soil is rendered cohesive and hardened past viscous strength. The section where flows were low at the bottom, co-ordinate to the deposition, was a bed load, the section where the change in concentration in volume fraction was realized was a suspended load, and that where smoothen flows were observed at the top was a launder load.

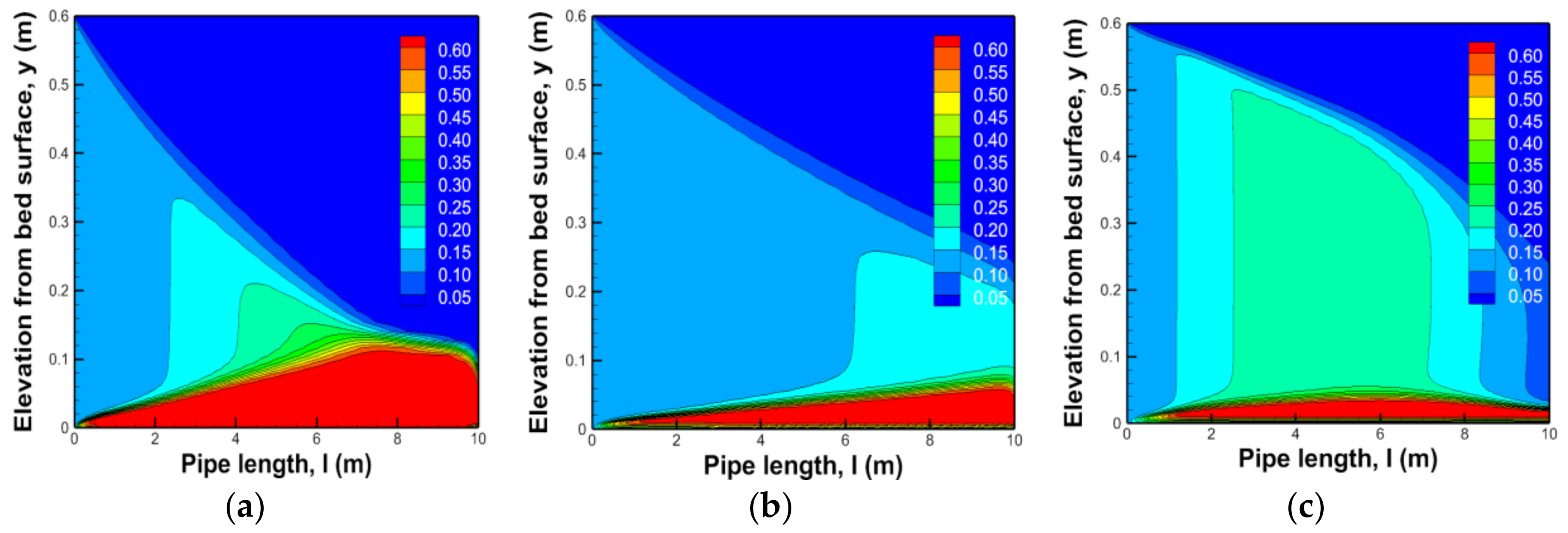

Effigy x shows the flow velocity distribution of soil forth the radial direction at the 1, v and nine m outlet positions along the longitudinal direction of the conduit as the volume fraction of slurry at the inlet was increased to 10%, xxx% and 50%, respectively, later on fixing the flow velocity of mixtures at 3 1000/due south and the particle size at three mm. y/D refers to a vertical position for a conduit bore. The biggest differences that depended on changes to the book fractions of soil at the inlet were in the distribution of soil and its flow velocity in the conduit. The distribution of soil and its period velocity influenced each other, and the uniformity of the menstruation velocity distribution indicates the uniformity of particle distribution. In all graphs, for the slurry input uniformly from the inlet, the soil was uniformly distributed over the unabridged bore of the conduit (0.6 one thousand), and the flow velocity of soil exhibited the period characteristics of turbulence.

At conduit lengths of 5 chiliad and 9 thousand, soil was deposited at the bottom of the conduit equally information technology passed through it so that flow velocity at the peak was close to zippo, and distribution therein appeared only at a region of deposits smaller than 0.3 chiliad effectually the outlet (Figure 10a). The flow velocity distribution of soil was considerably distorted from a parabolic form, so that the maximum menstruum velocity at the 0.3-thousand position was 3.four m/southward. The radial distribution of soil in the example in Figure 10b was seen to largely increase compared with that in Figure 10a, just the maximum flow velocity of soil occurred at the boundary between soil and water as shown in Figure 9 for the ten% volume fraction. For flow velocity distribution of soil of 50% the volume fraction status shown in Figure 10c, the distribution of soil was uniform up to the outlet of the conduit along the radial direction, in which case the distribution of soil was confirmed to accept a parabolic course. That is, as shown in Figure ten, as the book fraction at the inlet increased, the flow velocity distribution of mixtures at each position neared a parabolic class, which means that particles were more uniformly distributed in the transverse direction of the conduit.

iii.2. Changes in Pattern of Slurry Volume at Outlet

The fluids and soils inbound a mixed condition continually inverse in forms of distribution as they flowed through the conduit and deposited partially over time. This deposited soil gradually increased in quantity at detail positions of the conduit to cause an increase in local flow velocity at the corresponding section. Still, this phenomenon created a repeated form in a conduit to move toward the outlet, and finally discharged. At the end, this pattern was repeated to calculate the amount of deposition; thus, information technology was necessary to grasp the discharge design depending on flow velocity and concentration.

Based on the results of the analysis of 63 cases in this study, the menstruation distribution of fluids and soils in a conduit were observed to bear witness patterns of discharge of soil deposits from the outlet in three forms.

The graph of the inflow/outflow rates of slurry obtained from the obtained results is classified and listed in Figure xi. The offset instance (Effigy 11a) is a pattern where the soil outflow rate formed a cycle with a certain menstruum. This instance represents a physical miracle whereby the highest deposit of soil occurred at a certain catamenia and discharged from the conduit.

The deviation in deposition heights along the longitudinal direction of the conduit was clear. For this physical phenomenon, the inflow velocity should be relatively loftier and the size of soil particles maintained at a certain level considering deposition should occur. Therefore, the miracle based on this simulation occurred when the inflow velocity of mixtures was 3 thousand/s and the size of particles was relatively large. The second example (Figure 11b) shows a pattern where soil discharged at an virtually similar, constant rate to the arrival charge per unit without particular changes, excluding the initial phase. The trend of this outlet soil belch rate appeared primarily when the book fraction of soil in the mixture was equally large as 50% and the arrival velocity of the mixtures was equally depression as i.0 yard/s. The tertiary instance (Effigy 11c) is a blueprint in which the soil discharge rate gradually decreased at a certain catamenia, similar to the inflow rate after a certain time. This example can be regarded as an interim phenomenon betwixt the first and 2nd trends and appeared when the arrival velocity of mixtures was 2.0 m/south and the book fraction was 30%.

4. Prediction Model for Height of Particle Deposition in Sewer Conduits

This department is different from the previous sections considering the prediction model for summit of particle deposition is suggested. This report presents an empirical model formula to predict deposits in conduits of urban drainage systems through a degradation simulation based on inflow charge per unit, volume fraction, and the flow velocities of the fluids and soils inbound them. The formula should be able to predict the exact height of the deposit based on theories of transportation and precipitation because the deposition phenomenon during the transportation and precipitation of flowing soils has not been quantified in by studies.

The blocking of a conduit occurs at the position of the highest deposit of soil, not at its average top. This position was calculated at 63 simulation conditions based on volume fractions of soil in a mixture larger than 0.63, a marginal book fraction of eulerian analysis. The relations between the height of the deposit of soil and the inlet menses velocity of the mixtures, and volume fraction of inlet soil and particle size of soil were derived every bit correlation equations:

Equation (10) expresses the convective phenomenon in two-phase fluids equally a function of particle size and volume fraction using Equation (ix) and the Archimedes number based on the minimum fluidization velocity of moving particle

.

and

are the density and viscosity of a moving fluid,

is sedimentation velocity, g is gravitational acceleration, and

is the density of a moving particle [38].

To derive this correlation equation, nonlinear multivariable regression analysis was carried out, and the inlet flow velocity and particle size in the simulation weather were non-dimensionalized by Equation (9), with a Reynolds' number based on particle size. The minimum Reynolds' number for suspension was obtained using Equation (x) [38], which was used for vertical flows at showtime. However, given that the bore of the conduit was 120 times that of the maximum diameter of a particle in this written report, it was used for horizontal flows as well. Equation (eleven) refers to the Archimedes number used in Equation (ten).

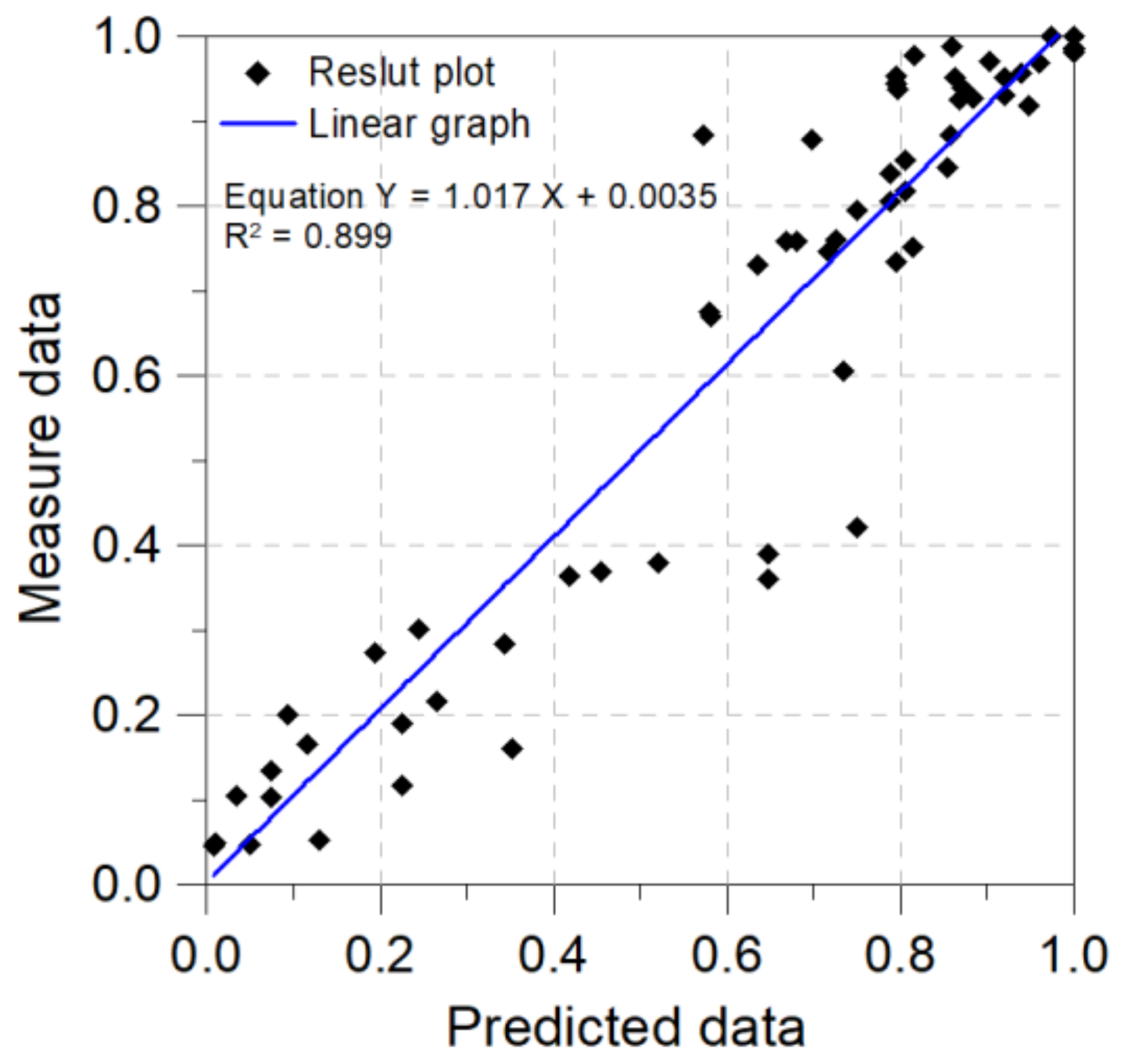

The height of the eolith of soil was non-dimensionalized using conduit diameters in Equation (12). As a result of the linear regression analysis between eolith height and the model, it a correlation coefficient (R2) of 0.877 was obtained. Withal, in the region where the soil deposition rate y/D was relatively loftier at 0.4, the deviation in the predictions increased. The rate of deposition increased as the soil book fraction and particle size increased. Thus, in the assay, the interaction betwixt the fluids and particles increased, and the degradation top showed small changes compared with various other weather condition. Equation (12) can thus be used within the weather of this analysis, and the flow of soil and slurry had various shapes and sizes of particles. Thus, these results as well as wider operation atmospheric condition should be reflected in modeling in future studies.

Yet, the predicted values in Effigy 12 were higher than the measured values in general because the onetime showed the condition in which blockage in the conduit was maximum. Moreover, the modeled values were closer to the measured values than the predicted values. It can thus be claimed that the modeled values were closer to the measured values than the only predicted values. Due to this uncertainty, it is necessary to check the suitability of assay and implement reasonable direction through the measured values past establishing a relation between them and the predicted values. By performing a unproblematic regression analysis on the measured data and the predicted data using a prediction formula to verify the usability of the regression equation, a conclusion coefficient of 0.899 was obtained to betoken high correlation.

The principal purpose of this report was to develop a methodology to review flow in a conduit. A performance indicator is the tiptop of the deposit in various conditions of inflow. The methodology should predict the discharge capacity in a conduit and be able to calculate circuitous features simply. Therefore, a correlation formula considering flow velocity, soil book fraction, soil diameter, and disquisitional eolith height was developed.

5. Conclusions

An important consideration in planning and designing drainage conduits is to prevent the deposition of soils and sediments inbound the conduit. In general, complicated phenomena occur whereby the belch cross-section of the conduit changes as transportation, atmospheric precipitation, and degradation occur. To properly design and efficiently maintain drainage conduits, information technology is necessary to check these phenomena. Belittling enquiry was conducted here on the flow characteristics of slurry in a conduit using the eulerian method, and the following conclusions can be made:

-

As the inflow velocity of soil particles in slurry is slow and the particle diameter is big, particles incline to the bottom of the conduit.

-

If the soil particles in slurry deposits nigh the inlet, flow velocity at the deposit increases, according to which the transportation of the deposited soil particles occurs.

-

Equally the flow velocity of incoming slurry is low and the bore of the soil particles big, the amount of the deposit increases and the stable transportation of slurry is interrupted.

-

The relations between the superlative of the soil deposited and the inlet flow velocity of mixtures, volume fraction of inflowing particle size, which were not-dimensionalized, were derived as a correlation formula.

-

Linear regression analysis between the deposit height and the model confirmed a correlation coefficient (Rtwo) of 0.877.

This study conducted analytical research on soil entering a drainage conduit using a numerical assay model. However, hydrodynamic analysis tin be used more finer than a comparison and review of predicted behavior and can be used to establish an improved programme and design a hydrodynamic construction in several fields. The final aim of this study was to derive a reasonable drainage conduit plan based on an verbal theoretical approach and careful analysis.

This result provides the necessary basis for the pattern of a drainage conduit and the assay of the blocking or breaking phenomenon of drainage conduits due to disasters such as landslides because of large corporeality of rainfall in the future. Withal, to review the flow phenomenon in a drainage conduit by considering the effect of the shapes of diverse types of soil and debris entering the conduits, it is necessary to review this nether various conditions by creating experiments and numerical models. Additionally, an improved sensitivity analysis of sediment parameters could be continued for the caption of sediment transport as a future study.

Acknowledgments

This research was supported by a grant [MOIS-DP-2015-03] through the Disaster and Safety Management Institute funded past Ministry of the Interior and Safety of Korean government.

Author Contributions

Yang Ho Song carried out the survey of previous studies and wrote the draft of the manuscript. Yang Ho Song and Eui Hoon Lee revised the draft until the last version of the manuscript. Yang Ho Song, Jung Ho Lee and Rin Yun obtained the results. Yang Ho Vocal, Rin Yun, Eui Hoon Lee and Jung Ho Lee conceived the original thought of the proposed method.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Perrusquia, One thousand. Bedload Transport in Storm Sewers: Stream Traction in Pipe Channels. Ph.D. Thesis, Chalmers University of Engineering, Göteborg, Sweden, 11 October 1991. [Google Scholar]

- Nalluri, C.; Ghani, A.A.; El-Zaemey, A. Sediment send over deposited beds in sewers. Water Sci. Technol. 1994, 29, 125–133. [Google Scholar]

- Kleijwegt, R.A. On Sediment Send in Circular Sewers with Non-Cohesive Deposits. Ph.D. Thesis, Delft Academy of Technology, Elft, The netherlands, eleven May 1992. [Google Scholar]

- Chebbo, Yard.; Bachoc, A. characterization of suspended soils in urban moisture weather discharges. Water Sci. Technol. 1992, 25, 171–179. [Google Scholar]

- Bertrand-Krajewski, J.L.; Barraud, S.; Kouyi, G.L.; Torres, A.; Lepot, M. Online monitoring of particulate pollutant loads in urban sewer systems: Stakes, methods, example of application. La Houille Blanche 2008, 4, 49–57. [Google Scholar] [CrossRef]

- Becouze, L.; Dembele, A.; Coquery, M.; Cren–Olive, C.; Barillon, B.; Bertrand-Krajewski, J.-L. Source characterisation and loads of metals and pesticides in urban wet atmospheric condition discharges. Urban Water J. 2016, 13, 600–617. [Google Scholar] [CrossRef]

- Nabil, T.; EL-Sawaf, I.; EL-Nahhas, Chiliad. Sand-water slurry flow modelling in a horizontal pipeline past computational fluid dynamics technique. Int. Water Technol. J. 2014, 4, i–17. [Google Scholar]

- Matousek, 5. Menstruum Machinery of Soil–Water Mixtures in Pipelines. Ph.D. Thesis, Delft Academy, Delft, The Netherlands, xv December 1997. [Google Scholar]

- Ota, J.J.; Perrusquia, G. Particle velocity and sediment transport at limit deposition in sewers. In Proceedings of the 12th International Conference on Urban Drainage, Porto Alegre/RS, Brazil, xi–16 September 2011; pp. i–8. [Google Scholar]

- Kim, C.H.; Han, C.H. Numerical simulation of hydraulic transport of soil–h2o mixtures in pipelines. Open J. Fluid Dyn. 2013, 3, 266–270. [Google Scholar] [CrossRef]

- Chen, L.; Duan, Y.; Pu, W.; Zhao, C. CFD simulation of coal-water slurry flowing in horizontal pipelines. Korea J. Chem. Eng. 2009, 26, 1144–1154. (In Korean) [Google Scholar] [CrossRef]

- Gopaliya, M.Grand.; Kaushal, D.R. Modeling of soil-water slurry flow through horizontal pipe using CFD. J. Hydrol. Hydromech. 2016, 64, 261–272. [Google Scholar]

- Onokoko, Fifty.; Galanis, N. CFD prediction of stratification in isothermal water ice slurry pipe flow. Int. Refrig. Air Cond. Conf. Purdue 2012, 2525, 1–7. [Google Scholar]

- Shi, Ten.J.; Zhang, P. Two-phase menses and heat transfer characteristics of tetra-n-butyl ammonium bromide clathrate hydrate slurry in horizontal ninety° elbow piping and U-piping. Int. J. Oestrus Mass Transf. 2016, 97, 364–378. [Google Scholar] [CrossRef]

- Tian, Q.; He, G.; Wang, H.; Cai, D. Simulation on transportation rubber of ice slurry in water ice cooling system of buildings. Energy Build. 2014, 72, 262–270. [Google Scholar] [CrossRef]

- Kaushal, D.R.; Tomita, Y.; Dighade, R.R. Concentration at the pipe bottom at degradation velocity for transportation of commercial slurries through pipeline. Power Technol. 2002, 125, 89–101. [Google Scholar] [CrossRef]

- Lorenzen, A.; Ristenpart, Eastward.; Pfuhl, Westward. Flush cleaning of sewers. H2o Sci. Technol. 1996, 33, 221–228. [Google Scholar]

- Bertrand-Krajewski, J.Fifty.; Campisano, A.; Creaco, E.; Modica, C. Experimental assay of the Hydrass flushing gate and field validation of affluent propagation modelling. Water Sci. Technol. 2005, 51, 129–137. [Google Scholar] [PubMed]

- Dettmar, J.; Staufer, P. Modelling of flushing waves for optimising cleaning operations. Water Sci. Technol. 2005, 52, 233–240. [Google Scholar] [PubMed]

- Campisano, A.; Creaco, East.; Modica, C. Numerical modelling of sediment bed aggradation in open rectangular drainage channels. Urban Water J. 2013, ten, 365–376. [Google Scholar] [CrossRef]

- Raquel, I.Southward. In-Sewer Organic Sediment Send. Ph.D. Thesis, Universitat Politècnica de Catalunya Barcelona Tech, Barcelona, Espana, October 2014. [Google Scholar]

- Crowe, C.T.; Schwarzkopf, J.D.; Sommerfeld, G.; Tsuji, Y. Multiphase Flows with Droplets and Particles, 2nd ed.; CRC Printing: Boca Raton, FL, Usa, 2012; pp. 8–9. [Google Scholar]

- ANSYS. ANSYS Fluent 12.ane Theory Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2010. [Google Scholar]

- Versteeg, H.M.; Malalasekera, Westward. An Introduction to Computational Fluid Dynamics, second ed.; Pearson Education Express: Hongkong, Red china, 2007. [Google Scholar]

- Boris, V.B.; Alex, C.H.; Pawel, K.; Lee, D.R. Eulerian–Eulerian CFD model for the sedimentation of spherical particles in break with high particle concentrations. Eng. Appl. Comput. Fluid Mech. 2010, iv, 116–126. [Google Scholar]

- Lixing, Z. Two-phase turbulence models in Eulerian–Eulerian simulation of gas particle flows and coal combustion. Procedia Eng. 2015, 102, 1677–1696. [Google Scholar]

- Zhen, C.; Tian-Jian, H.; Joseph, C. SedFoam. A multi-dimensional Eulerian two-phase model for sediment transport and its application to momentary bed failure. Declension. Eng. 2017, 119, 32–50. [Google Scholar]

- Everitt, B.South.; Hand, D. Finite Mixture Distributions; Wiley & Sons, Inc.: London, Britain, 1985. [Google Scholar]

- Jones, Westward.P.; Launder, B.E. The Prediction of Laminarization with a 2-Equation Model of Turbulence. Int. J. Heat Mass Transf. 1972, 15, 301–314. [Google Scholar] [CrossRef]

- Syamlal, M.; O'Brien, T.J. Fluid dynamic simulation of O3 decomposition in a bubbles fluidized bed. AIChE J. 2003, 49, 2793–2801. [Google Scholar] [CrossRef]

- Syamlal, M.; O'Brien, T.J. The Derivation of a Drag Coefficient from Velocity-Voidage Correlation; National Energy Engineering Laboratory: Morgantown, WV, U.s., 1994; Unpublished Report. [Google Scholar]

- Syamlal, M.; O'Brien, T.J. Computer simulation of bubbles in a fluidized bed. AIChE J. 1989, 85, 22–31. [Google Scholar]

- Taghipour, F.; Ellis, Northward.; Wong, C. Experimental and computational study of gas–soil fluidized bed hydrodynamics. Chem. Eng. Sci. 2005, 60, 6857–6867. [Google Scholar] [CrossRef]

- Hernández-Jiménez, F.; Sánchez-Delgado, Southward.; Gómez-García, A.; Acosta-Iborra, A. Comparison between two-fluid model simulations and particle image assay and velocimetry (PIV) results for a 2-dimensional gas–soil fluidized bed. Chem. Eng. Sci. 2011, 66, 3753–3772. [Google Scholar]

- Kalambe, A.R. Ii-Phase Flow CFD Analysis of Refrigerants in a Condenser Pipe for Prediction of Pressure Driblet and Pumping Power. Master's Thesis, The University of Texas, Arlington, TX, U.s., 2015. [Google Scholar]

- Wilcox, D.C. Turbulence Modeling for CFD; DCW Industries, Inc.: La Cãnada, CA, Usa, 2006. [Google Scholar]

- Park, C.W.; Hong, C.H. User Guide of ANSYS Workbench; Intervision: Seoul, Korea, 2008.

- Wen, C.Y.; Yu, Y.H. A generalized method for predicting the minimum fluidization velocity. AIChE. J. 1966, 12, 610–612. [Google Scholar] [CrossRef]

Figure 1. Horizontal pneumatic transport. (a) Homogeneous flow; (b) Dune catamenia; (c) Slug flow.

Figure 1. Horizontal pneumatic transport. (a) Homogeneous flow; (b) Dune flow; (c) Slug period.

Figure 2. Flowchart of analysis process.

Figure 2. Flowchart of assay procedure.

Figure three. Comparison of the velocity of the simulated mixture (m/southward) with that in experimental results [7].

Figure 3. Comparison of the velocity of the simulated mixture (m/s) with that in experimental results [7].

Figure 4. Comparison of the false soil volume fraction (%) with that in experimental results [7].

Figure 4. Comparison of the simulated soil book fraction (%) with that in experimental results [7].

Figure 5. Conduit mesh.

Figure vi. Sedimentation results for soil of diameter i.0 mm according to changes in book fraction; (a) Volume fraction 10%; (b) Volume fraction thirty%; (c) Volume fraction 50%.

Effigy 6. Sedimentation results for soil of diameter 1.0 mm according to changes in volume fraction; (a) Volume fraction 10%; (b) Volume fraction 30%; (c) Volume fraction 50%.

Effigy seven. Sedimentation results for soil of diameter 20.0 mm according to changes in volume fraction. (a) Volume fraction 10%; (b) Volume fraction xxx%; (c) Volume fraction fifty%.

Figure seven. Sedimentation results for soil of diameter 20.0 mm according to changes in volume fraction. (a) Volume fraction 10%; (b) Volume fraction 30%; (c) Book fraction 50%.

Figure viii. Sedimentation results for soil of diameter 1.0 mm co-ordinate to changes in inlet velocity. (a) i.0 m/southward inlet velocity; (b) 2.0 1000/s inlet velocity; (c) 3.0 thou/due south inlet velocity.

Figure 8. Sedimentation results for soil of bore 1.0 mm according to changes in inlet velocity. (a) one.0 m/s inlet velocity; (b) two.0 k/southward inlet velocity; (c) 3.0 grand/s inlet velocity.

Effigy ix. Sedimentation results for soil of diameter 20.0 mm co-ordinate to changes in inlet velocity. (a) 1.0 m/southward inlet velocity; (b) 2.0 thousand/due south inlet velocity; (c) three.0 m/s inlet velocity.

Figure 9. Sedimentation results for soil of diameter 20.0 mm co-ordinate to changes in inlet velocity. (a) i.0 m/south inlet velocity; (b) 2.0 chiliad/south inlet velocity; (c) 3.0 chiliad/s inlet velocity.

Figure 10. Soil velocity and soil bore according to modify in volume fraction. (a) Soil velocity distribution at a volume fraction of 10%; (b) Soil velocity distribution at a volume fraction of 30%; (c) Soil velocity distribution at a volume fraction of 50%.

Figure x. Soil velocity and soil bore according to alter in volume fraction. (a) Soil velocity distribution at a volume fraction of x%; (b) Soil velocity distribution at a book fraction of 30%; (c) Soil velocity distribution at a volume fraction of fifty%.

Figure 11. Flow patterns and characteristics diagram in sewer. (a) Moderately damped oscillation; (b) Oscillation design; (c) Highly damped oscillation pattern.

Figure eleven. Period patterns and characteristics diagram in sewer. (a) Moderately damped oscillation; (b) Oscillation pattern; (c) Highly damped oscillation pattern.

Figure 12. Correlations between simulated results and predicted results by Equation (12).

Effigy 12. Correlations between simulated results and predicted results by Equation (12).

Table ane. Standard g–ε model parameters.

Table one. Standard thou–ε model parameters.

| 0.09 | i.44 | i.92 | 1.0 | 1.3 |

Table 2. Conditions of analysis in FLUENT.

Table 2. Conditions of analysis in FLUENT.

| Condition | Setting |

|---|---|

| Type | Fluid |

| Textile | Water |

| Turbulence Model | k–ε standard |

| Inlet | Velocity = 1.0–three.0 m/s |

| Outlet | Relative pressure level = 0 (Pa) |

| Wall Influence of Flow | No slip |

| Surface Influence of Menstruation | Free slip |

Tabular array 3. Simulation conditions for comparison with experimental results.

Tabular array iii. Simulation conditions for comparison with experimental results.

| Championship | Soil–Water Transport |

|---|---|

| Geometry | x.55 thousand × 0.015 m |

| Model | Eulerian–eulerian model, Turbulent catamenia |

| Mixture boundary Conditions | Inlet velocity: 3 yard/s, Inlet volume fraction: 30% |

| Soil | Density: 2650 kg/kthree, Particle diameter: 0.2 mm |

| Water | Density: one thousand kg/g3, Dynamic viscosity: 0.001004 Pa·s |

Table 4. Parameters of standard k–ε model.

Table iv. Parameters of standard k–ε model.

| Titles | Conditions | |

|---|---|---|

| Geometry | 0.6 thousand (D) × ten m (L) | |

| Model | Eulerian–eulerian model, Turbulent flow | |

| Mixture boundary Conditions | Inlet Velocity (m/s): | 1.0, 2.0, 3.0 |

| Inlet Volume Fraction (%): | 10, 30, 50 | |

| Soil | Density (kg/k3): | 2650 |

| Particle Bore (mm): | 0.5, 1.0, 3.0, 5.0, vii.0, 15.0, 20.0 | |

| Water | Density (kg/10003): | 1000 |

| Dynamic Viscosity (Pa·s): | 0.001004 | |

Tabular array 5. Sedimentation results for soil of diameter 1.0 mm and 20.0 mm according to changes in book fraction (where the soil deposition charge per unit h/D).

Table 5. Sedimentation results for soil of bore i.0 mm and 20.0 mm according to changes in book fraction (where the soil deposition charge per unit h/D).

| Volume Fraction | 10 | 30 | l | |

|---|---|---|---|---|

| D (mm) | ||||

| ane.0 | 0.160 | 0.365 | 0.884 | |

| 20.0 | 0.629 | 0.938 | 0.967 | |

Tabular array vi. Sedimentation results for soil of diameter 1.0 mm according to changes in inlet velocity (where the soil deposition charge per unit h/D).

Table 6. Sedimentation results for soil of diameter 1.0 mm co-ordinate to changes in inlet velocity (where the soil deposition rate h/D).

| Velocity (m/south) | i.0 | 2.0 | three.0 | |

|---|---|---|---|---|

| D (mm) | ||||

| i.0 | 0.160 | 0.053 | 0.047 | |

| 20.0 | 0.629 | 0.552 | 0.518 | |

© 2018 past the authors. Licensee MDPI, Basel, Switzerland. This commodity is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC By) license (http://creativecommons.org/licenses/by/4.0/).

Sedimentation Software Free Download Mac Based on Particle Size Fractions and Volume Fraction

DOWNLOAD HERE

Source: https://www.mdpi.com/2073-4441/10/4/462/htm

Posted by: kreutzerhaterrovat.blogspot.com